By order of ZAO European Technologies and Service, the Metropolis company developed part of the working documentation for a multifunctional sports and recreation complex for family recreation and health rehabilitation in Moscow. The commissioning of the complex is scheduled for 2012. At present, after 3 months of work and the widespread use of the Allplan Design module, the development of the constructive section of the working documentation has been successfully completed.

Sports and recreation complex for family recreation and rehabilitation "Oasis"

In the southern part of Yasenevo, surrounded by a birch forest, at the confluence of the Bitsa River and the Yasenevsky Creek, a unique park is being built that has no analogues in Russia, combining traditional and modern developments in the field of recreation and health improvement. The decision to build a multifunctional sports and recreation complex for family recreation and health rehabilitation was made in 2004, the commissioning of the complex is scheduled for 2012. The authors of the project (Tekhstroy construction company) tried to make the most of the rich natural environment, combining the space of the complex and forest park surrounding it.

The scale and content of the complex is evidenced by its area of 54,600 m2 and the official name - "Multifunctional sports and recreation complex for family recreation and health rehabilitation and a temple-chapel." According to the space-planning decision, the object is a modern complex and large-scale composition, in which the temple-chapel plays the dominant role (despite its small size).

Operating as functional zones there are:

- a rehabilitation center, visiting which you can be transported to the shore of a forest lake, where everyone can recuperate, get rid of stress, restore physical condition after injuries;

- a bath complex with eight types of saunas of different temperature effects and design, Russian and Turkish baths;

- a fitness center surrounded by a green winter garden;

- a SPA center, the concept of which is based on the theme of the Mediterranean resorts;

- a water park with many water attractions, hot tubs, pools and play areas for children.

Embodiment of the idea into reality: setting the task

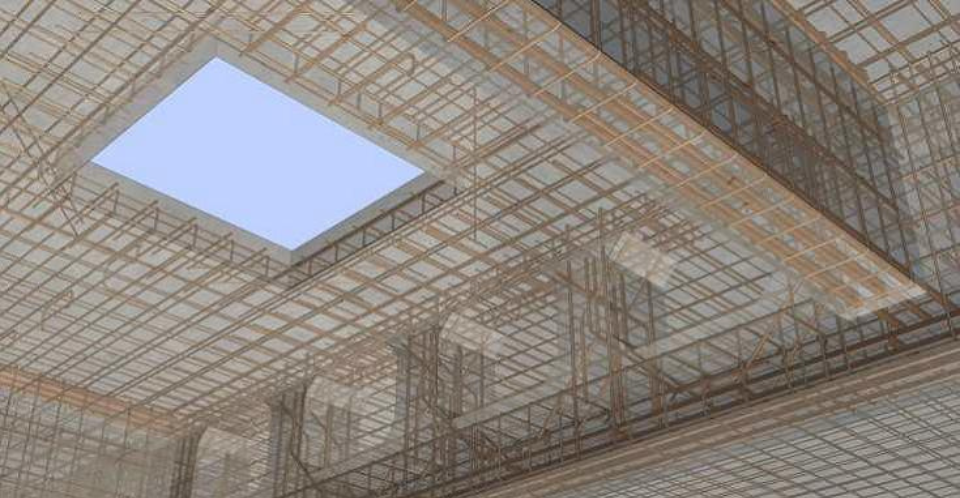

The tasks of Metropolis included the development of detail design for the structural section of two of the six buildings of the complex: the office and administrative building, the entrance recreational building and the transition structure. The buildings under consideration are a 3-storey building with a 1-level underground car park with a monolithic reinforced concrete frame. The pitch of the columns is predominantly 6.0 x 6.0 m.

The above-ground part of the structure is represented by a 3-storey structure of complex configuration in plan (in the form of a winding horizontal ribbon). Columns, ceilings, walls and stairs are monolithic reinforced concrete. The foundation is pile-slab. The task of design and construction was complicated by the fact that part of the structures of one of the buildings had already been erected. The project provided for the dismantling of some structures and the preservation of some of the existing ones. (Existing hull designs are shown in orange in the illustration below.)

At all stages of the design of this object, the design engineers of Metropolis used Allplan Design: to obtain formwork drawings, reinforcement, layouts of structures, assemblies and parts, and to obtain all the necessary specifications.

Comprehensive benefits of a single design process

Olga Birichevskaya

Olga Birichevskaya

According to Olga Birichevskaya, Chief Structural Engineer of Metropolis, the use of Allplan made it possible to solve a whole range of tasks typical of the design process. First of all, Allplan made it possible to achieve absolute uniformity in the issued documentation by introducing a standard for the design of project documentation. The “Bureau Standard” of the company was formed taking into account all the peculiarities of paperwork in Metropolis and the current standards.

Also, Allplan provided the ability to store and conveniently use the company's typical developments: standard units and parts are easily accessible to each project participant. Using the symbol catalog, the engineer no longer needs to refer to old company designs to apply a previously used generic solution.

Thanks to such tools as Building Structure, Plane Manager and Drawing Structure, a clear and transparent project layout was built during the design process, easily accessible and understandable for use, starting from the model and its derivatives (plans and sections) and ending with drawing sets.

The proposed building has a complex configuration in terms of layout. Each overlap in it is unique.

The design process was complicated by the fact that during the development of the working documentation of the structural section, it was necessary to adapt to frequent changes in the architecture, including floor contours. By means of Allplan it was possible to make changes quickly and painlessly. Although the presence of curved elements complicates the process of calculating the consumption of materials, Allplan coped with this task easily.

As noted above, part of the existing building structures in the project is dismantled, while the other part is preserved. The Transform to Reconstruct tool was a great help when working with these elements. This tool makes it easy to classify structures as "dismantled", "preserved" or "newly erected". This contributes to the understanding of the work of structures and the vision of the project as a whole due to visual visualization and differences in the displays of existing and newly erected structures.

Also in the project there are elements with very rich reinforcement - beams with openings for the passage of engineering communications. The use of the "Reinforcement with model" mode made it possible to examine in more detail the knots of complex conjugations of elements and to control the collisions of reinforcing bars.

In conclusion, Olga Birichevskaya notes another important advantage of Allplan: “As a colossal advantage, it is worth noting that young specialists who are just starting their professional path, developing one or another part of the project, no longer perceive the design as some kind of abstract lines on the drawing, but understand what it is "in real life". They see the structural scheme of the building in volume.

Simplicity and benefits of parallel work in 2D and 3D

Thanks to the ubiquitous use of 2D and 3D modes, the design engineers of Metropolis have been able to take many advantages from combining these two methods of work. Guided by the principle “to model everything that can be modeled”, 3D models of the building, individual parts of structures and assemblies were created. This method made it possible to remove all the necessary types of sections, views and nodes from the existing 3D model, and also provided the ability to quickly and easily edit the model and drawings based on it. Refinement of nodes, sections and cuts, as well as part of the reinforcement work was carried out using 2D modules. As Olga Birichevskaya explains: “Even if you start working in 3D, you can easily continue working with the project in 2D and vice versa.” Ease of switching between 2D and 3D work modules at any design stage has made the design process more visual, malleable to any changes, which is a very important factor in today's design conditions.

The process of exchanging data with third-party project participants

We exchanged data and issued assignments to related sections by importing Allplan drawings into DWG and PDF formats. This tool is implemented in Allplan in the best possible way. Data is transferred to the DWG format with exceptional accuracy. What's more, even the formatting of documentation transferred to DWG format complies with our corporate standard. Thus, the customer, architect and other project participants receive reliable information from us with the ability to view, print, make adjustments and comments in a form convenient for them.

Interaction of design participants in a team

Thanks to the capabilities of Allplan, we have achieved absolute transparency in the design process. Now a group of engineers at each stage of project development is in a single Allplan environment, working on a single building model. With Allplan tools such as Project Structure and Drawing Structure, the exchange of data between project participants has become streamlined and technically simple. Changes made by one of the participants are immediately available to the entire design team. Each of the participants has access to data on decisions made in other parts of the project. The procedure for issuing tasks, monitoring and verifying the fulfillment of assigned tasks is greatly simplified.

Why Allplan?

At a certain stage, we have reached our limit in the use of traditional 2D design methods. To obtain an additional effect in the speed of development and the quality of the released projects, a new approach to solving the tasks was needed - an approach that allows you to easily cope with modern design conditions. Currently, projects are developing very dynamically, constant coordination with other project participants is required, the decisions made are adjusted to the wishes and requirements of the customer, the architect, and specialists from all engineering departments. Modern buildings are a living organism, serving to ensure the comfort of people who live, work and play in its environment. In order to build such an organism, the design process must be very well organized and debugged.

Taking into account these features, a product was needed, in which, if not all, then almost all the needs of the designer were realized at a professional level from a sketch to the stage of detail design. Allplan allowed us not only to work with great comfort, but also to achieve the desired effect - to reduce design time and improve the quality of released projects, to reduce the likelihood of errors and collisions. Allplan has changed the approach to work, now every employee involved in the project is engaged in designing, not drawing.